Fit into hibernation - Prepare for the coming season - Part 2

In autumn, lawnmowers, ride-on mowers and countless other garden tools can shift down a gear. Most of the work is done and there is more time to take care of maintenance, repairs and servicing.

The second part of our Winter Check-up series focuses on the engine, the electrical system and tyres. We asked the engine expert Wolfgang Gerlach from AS-Motor what needs to be considered.

Wellness for the engine

The good news for all owners of electric or battery mowers is that electric motors are normally maintenance-free. Only occasionally do air filters need be cleaned.

In the case of internal combustion engines, on the other hand, a number of points need to be worked through. We start with the air filter. This is removed and then checked for impurities. Dry dust, plant seeds and foreign objects can be removed by light tapping. Damaged, heavily soiled, or oil- and petrol-contaminated filters must be replaced. Our AS-Motor expert points out that when replacing a filter, you should always use original parts from the manufacturer. You can recognize AS-Motor filters, for example, from the logo on the filter. Unfortunately, there are many inferior copies available at the moment. Engine damage caused by copied filters is becoming more and more common. In addition, the dryness of the last few years has considerably increased the motors’ dust load. Therefore, it is advised to shorten one’s interval of inspecting air filters during the current season.

If the machine’s engine has run properly before the winter break, there is no need to unscrew and clean the spark plug. In this case, one must only be attentive to malfunctions and the engine manufacturer’s next prescribed service interval.

Engine damage caused by inferior copies is unfortunately not uncommon. The picture shows a new original air filter, a dirty original air filter and a cheap copy (from left)

Empty carburettor and tank

You must clean the carburettor carefully from the outside. Make sure that you do not damage any tension springs or loosen any screws. For 4-stroke engines the carburettor should also emptied before storage. To do this, close the fuel tap, start the engine and allow it to drain by letting the engine run until it stops by itself. There will still fuel left in the fuel filter and the fuel line, but the carburettor will be almost completely empty. Some carburettors also have a drain plug for the remaining fuel. Use this, if available.

Try to empty the petrol tank as much as possible during the last mowing. In the spring, fill up with fresh fuel. Machines with metal tanks are better equipped to avoid corrosion and condensation.

For machines with 2-stroke engines (except chainsaws and brush-cutters) the carburettor must also be emptied for storage. Proceed here as with a 4-stroke engine. It is also advisable to empty the fuel tank afterwards, as the 2-stroke mixture could segregate over the winter and cause engine damage in spring. Leave the fuel tank ventilation open. However, the fuel tap should remain closed. Otherwise the tank could dent or expand due to temperature differences. Basically, the following applies to 2-stroke mixtures: Only use fully synthetic 2-stroke oils. Mineral oils have become obsolete.

Our engine expert also points out that the oil in the fuel mixture of 2-stroke engines may stick to the fuel filter during the winter period and recommends: “Buy your 2-stroke mower a new fuel filter in the spring. This costs little and prevents starting problems and uneven engine running.”

Winterise batteries properly

Regarding the electrical system, one should first visually inspect the cables, the wiring harness, the plugs, the covers and the cable fastenings.

Please note the following in regards to the batteries. Maintenance-free wet and gel batteries are used in ride-on mowers today. Maintenance-free means that no acid or water needs to be refilled. It does not mean, however, that the battery does not need to be regularly charged when not in use and thus maintained. Once a battery is deeply discharged, it will suffer permanent damage. Therefore, if there is a risk of frost during storage, it is recommended that the battery be removed and stored in a dry place at 15 to 18° Celsius. The same applies to Li-Ion batteries. The batteries of ride-on mowers should also be charged at least once a month. So-called continuous maintenance chargers with intelligent electronics are particularly helpful for this. These are already available for around 20 euros in car accessory shops. Li-Ion batteries should be stored with a charge level of about 50 percent. In principle, batteries must be stored in a fireproof place, e.g. in a steel cabinet or metal box. Damaged Li-Ion batteries in particular pose an increased fire risk.

Clean cooling and sufficient oil

The petrol engines of ride-on mowers and combustion lawnmowers are usually air-cooled. The cooling air intake’s ventilation grid must be cleaned during the winter check-up. Also check, if possible, that the cooling fins of the engine are clean and the air baffles intact. However, cleaning and full inspection can only be carried out by a specialist dealer, as the cooling system is fitted with motor covers. Remember that dirty cooling fins can cause the motor to overheat.

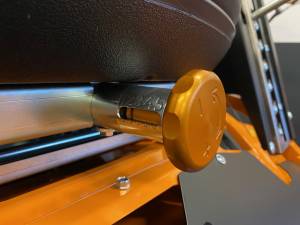

For 4-stroke engines, check the oil level with the dipstick. If there is any oil missing, top up with the required amount up to the maximum mark. Make sure to observe the oil change and oil filter service intervals for the engine, the hydrostat and if necessary, the gearbox. This check is not necessary for 2-stroke engines as they do not contain engine oil.

For 4-stroke engines the oil level must be checked and, if necessary, missing oil topped up.

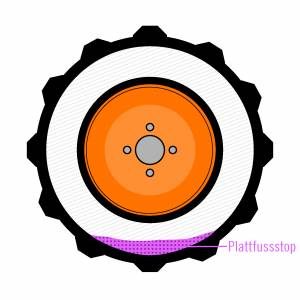

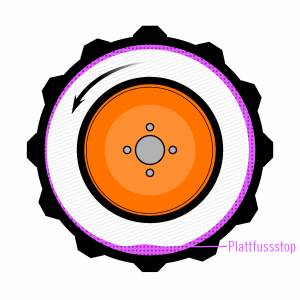

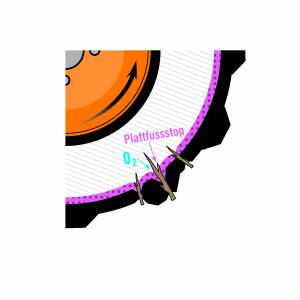

It is worthwhile to fill in a tyre sealant, especially for tubeless tyres. Downtimes are thus significantly reduced

The right pressure in the tyre

Ride-on mowers and garden tools travel at low speeds. It is not necessary to jack up the machines to avoid standing dents on the tyres. A few maintenance and control measures do make sense, however. Inflate the tyres to slightly higher operating pressure. Then the tyres should be checked for cracks, cuts, porosity, spikes and dents. You should also check whether any foreign bodies are between the rim flange and the tyre, and whether the wheel bolts are tight. In the case of tubular tyres, it is also necessary to check whether the valve is straight or has shifted. If necessary, the air must be deflated and the casing aligned, otherwise there is a risk of the valve shearing off.

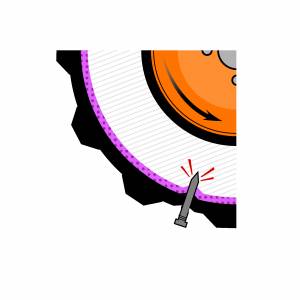

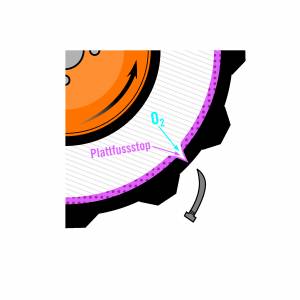

As with every tyre, but especially with tubeless tyres, it is worth considering a tyre sealant. This greatly reduces downtimes as tyres can function even with many thorns stuck in the tyre. Tyres with sealant can lose some of their pressure if left standing for a long time. This is normal, as the sealant is distributed and can only work to its full effect when the tyre is driven regularly. Simply inflate these tyres again in spring and drive a few metres. Shortly before the start of the season, check again whether all tyres are still inflated or whether there are any “sneakers”. In this way you can avoid a negative experience at the beginning of the new season.

The new season can come!

Now your machines are ready for hibernation. They should be ready for use immediately at the start of the coming mowing season, without any annoying surprises, provided that you have written down any defects discovered during the check-up and had them corrected or repaired. Take advantage of the quieter winter months at your specialist dealer to have necessary repairs carried out in peace. Please always entrust work on blades and safety components to a specialist. We wish you happy working and good mowing in the next season.